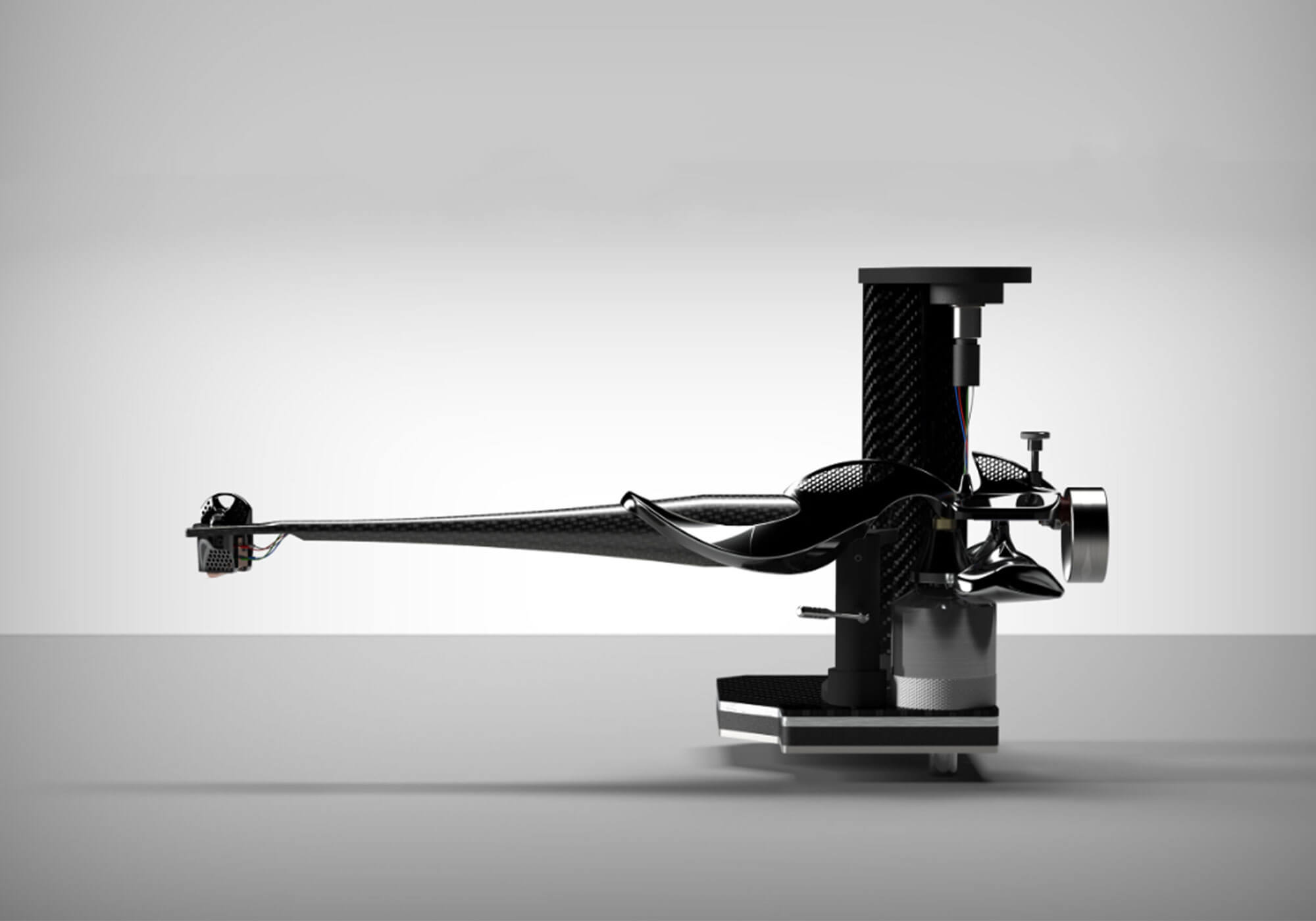

Wilson Benesch GRAVITON® Ti Tonearm Dohmann Edition

Put simply, there will never be another tonearm like this. The development of the GRAVITON® Ti tonearm is a ‘perfect storm’ of rare ingredients coming together to create something extraordinary. This is a piece of equipment with a level of research, engineering, design intelligence and manufacturing technique that is not only unprecedented but is so far beyond any other tonearm in the world, it should probably define a new class ‘hyper-audio’.

Sonics are subjective, however when you apply this level of technology to address traditional challenges of tonearm design, it is inevitable that substantial improvements in sonic performance will follow and the GRAVITON® Ti does not disappoint. This is why we decided to enter into a collaboration with Wilson Benesch in order to develop a special version of this tonearm for Dohmann Audio turntables.

Who are Wilson Benesch?

- Founded in 1989 and located in Sheffield, England, Wilson Benesch is a globally recognised brand that is synonymous with excellence, designing and manufacturing some of the world’s most desirable high-end audio products.

- Their participation in UK government initiatives such as the SSUCHY Project over the years has provided significant funding which has been used to develop technologies that have never been applied in audio before.

- One of the most innovative companies in high-end audio, especially in materials science. They were the first in the world to use carbon fibre in turntable and tonearm applications and in recent years, the first in the world to use bio-composite materials (biocarbon) in speaker cabinets.

- Wilson Benesch is entirely family owned and 95% of their inventory of components used to produce their products are created entirely in-house from raw materials.

The world’s first carbon fibre armwand back in 1989!

Wilson Benesch was the first audio manufacturer to produce a tonearm manufactured with carbon fibre (the A.C.T. One tonearm) all the way back in 1989. This was a time when carbon fibre was virtually only being used in military, aerospace and Formula One applications. Their research indicated that advanced composite materials would offer superior specific stiffness and damping to metal. To verify if these materials translated into a sonic performance advantage WB conducted extensive trials using a test rig with a detachable cartridge head. Multiple materials including aramids, glass, carbon and various hybrid constructions were tested and evaluated. Decades later during the SSUCHY Grant Project, WB collaborated directly with the FEMTO Institute, France, who tested the function of these materials at both the macro and micro level providing peer reviewed scientific data for the first time that underlined the properties of advanced composite materials. The SSUCHY Project research concluded that the balance of stiffness and damping selected by WB in 1989 was close to optimal underlining the empirical observations made at the time. The research concluded:

- The hyperbolic curve of the arm is the optimum geometry for a beam. Providing zero redundancy of materials, being progressively smaller in diameter the further away it gets from the pivot point.

- The woven fabric 0/90-degree fibre orientation in the carbon fibre fabric orientates the fibres in a helix like DNA which provides maximum torsional stiffness.

- The 0/90 fibre orientation also increases surface area; if the length of the fibres down the length of the armtube are increased, the pathway that energy must travel down the tube is increased. As this energy travels down the long fibres, it meets with millions of fibre boundaries created by the fibres oriented in the other axis, each fibre is therefore a barrier and a point at which this energy can be damped and dissipated. The 0/90 orientation therefore also delivers orders of magnitude superior damping.

- Moulded as a single piece construction including the armtube and headshell, the component is one functional engineering structure that omits discontinuities where one component is bolted to another which in turn can create a reflective boundary to energy being transmitted down the armtube. If the objective is to damp energy, bolted headshells are a compromise to the tonearm structure.

It took many years to become an overnight success

Although inspired by Wilson Benesch’s Design Director Craig Milnes, the development of the GRAVITON® Ti was a collaborative effort by many people over many years. Unusual for a designer of audio equipment, Craig Milnes’s journey included a Fine Art degree, a specialisation in sculpture and a lifetime of work in design, engineering and materials science. Inspired by his understanding of anatomy, geometry and structures informed by nature, Craig created a wax model of the form and shape of the counterbalance structure and then shared it with Dr James Hunt and his team at The University of Sheffield. Dr Hunt and his students then applied their expertise and knowledge of additive manufacturing technology and also some generative design tools to further optimise and evolve the structure.

In addition to the unique opportunity of accessing this kind of expertise in the AMRC (Advanced Manufacturing Research Centre ) and The University of Sheffield through grant funding and their geographical position close to these centres of excellence, Wilson Benesch was also able to then collaborate with Renishaw PLC – one of the leading companies in titanium additive manufacturing technology globally – because Renishaw machines are used at the AMRC. Renishaw then helped refine the parts for end product production. And running parallel to this, the FEMTO Institute with Prof. Morvan Ouisse was testing the structures that evolved to verify the data correlated with the theory.

We were immediately intrigued

At Dohmann Audio, we have spent many years measuring and studying the behaviour of resonance energy within analog audio systems. We have gained some understanding regarding geometric shapes that minimise resonance, materials that work well in these environments and engineering designs that we know make a difference. When we first became aware of the GRAVITON® Ti, we could immediately tell that it was based on genuine science and would most probably be ‘next level’ in performance.

We reached out to Wilson Benesch and in May 2024, George Moraitis visited their factory and had a tour of the AMRC in Sheffield, England. The AMRC park, now a state-of-the-art advanced manufacturing centre, has expanded to over 150 acres with more than 90 industrial members, including giants like Boeing, Rolls-Royce, McLaren and BAE Systems. Through a collaboration with Sheffield University, the AMRC has become a centre of excellence in materials science and manufacturing technologies. Some industry applications have benefitted, such as jet engine turbine development, high tensile composites for aerospace applications and most importantly… tonearms!

The armtube

Wilson Benesch had experience with carbon fibre armtube design with the A.C.T. One tonearm decades earlier, which was used as a starting reference point. The single piece moulded, tapered GRAVITON® Ti armtube is further evolved and advanced through the addition of uni-directional carbon fibre and a Rohacell sandwich section. Data provided by The Sheffield Hallam University demonstrates the exceptional strength and rigidity of the armtube; a notable data point shows that under a maximum stress force of 1,232psi, the deflection of the armtube is just 0.003mm. This remarkable stiffness ensures that the highest resonant frequency is attained. The external and internal shape and dimensions of the armtube were the result of simulations and modelling based on creating the most efficient shape possible for resonance mitigation.

Inspired by geometries found in nature

Triangular, hexagonal and specific geometric forms have developed over millions of years of evolution and appear literally everywhere in nature, including cells, organs, bone structures, plant anatomy, bee hives…etc. For example, if you were to look at the construction of human and animal bones under a microscope, you can appreciate the design as a sequence of interlocking triangular or latticed structures. The triangle is commonly seen in many structures, including the truss in architecture and represents the most economical form to create a rigid structure.

Many years before Wilson Benesch was established, Craig Milnes was fascinated by geometries evident in nature and studied this topic with great interest. In fact, evidence of this ‘biomimicry’ runs through the entire history of design at Wilson Benesch and can be observed in all of their products dating back to the very first. When conceiving this new tonearm design, Craig knew that an optimal tonearm design had to incorporate these shapes, structures and principles. It was fortunate that building such an ambitious design was now possible using modern SLS Manufacturing Technology which inspired Craig to work with Dr. Hunt and his team. The design was developed and optimised in the final stages using generative design that would look at specific areas of the tonearm and produce multiple possible solutions that were informed by an algorithm that had a deep understanding of natural geometry and nature.

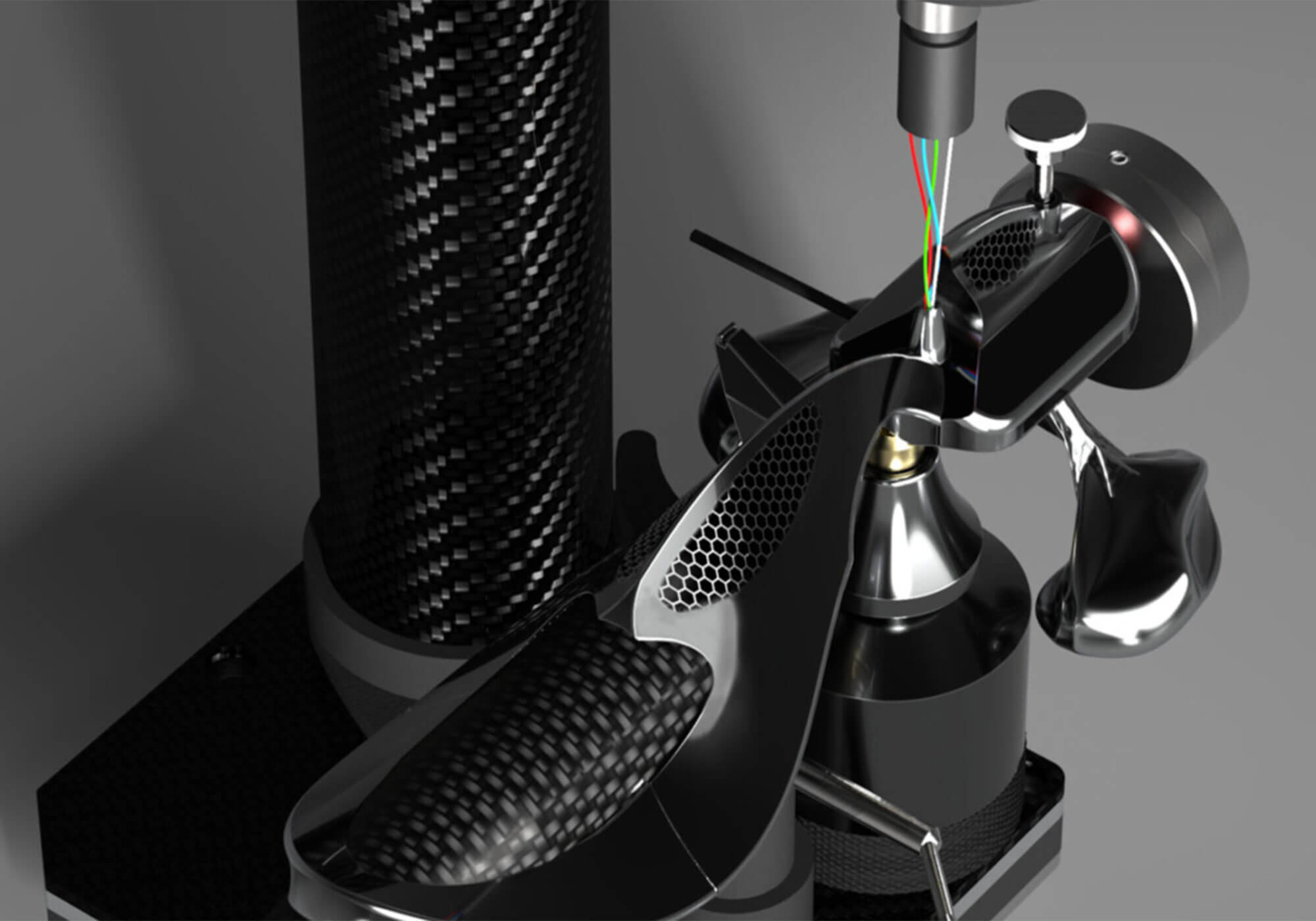

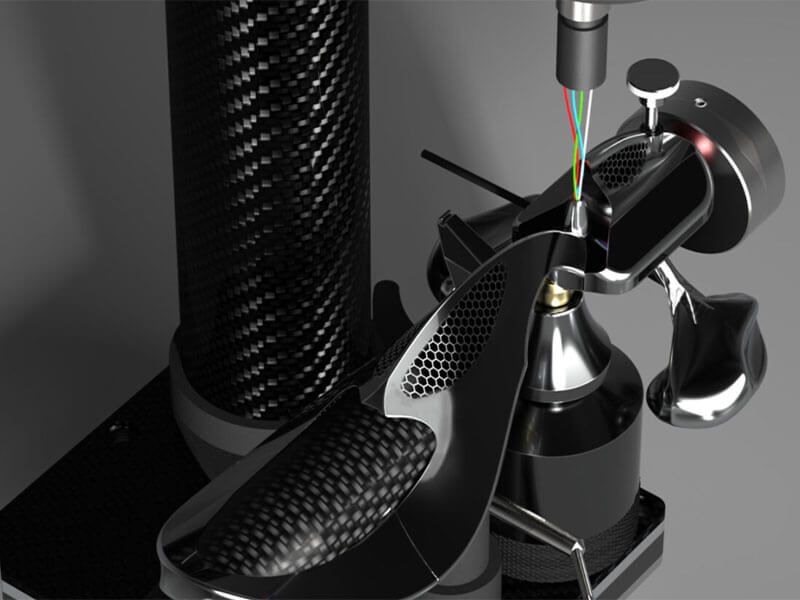

If you look at the shapes formed by the titanium section of the armwand, it is a series of triangles using curved forms between each ‘point’. This optimises stiffness, whilst also resulting in almost zero material redundancy. If you observe the structure from the side you can see that there is almost no material above the pivot point of the arm which is optimal for maintaining a low centre of gravity. What you can’t see is that hexagonal shaped structures are also inside the titanium structure creating incredible stiffness, whilst also reducing mass as much as possible. Furthermore, introducing these shapes into a metal which is an isotropic material gives the component an anisotropic characteristic which provides multiple advantages – directional flow of energy, superior damping, optimised stiffness to mass – it mimics natural systems!

Design, technology and engineering taken to an extreme

Take a moment to think of the counterweight design of virtually every tonearm you have ever considered. They usually consist of solid metal weights that you can rotate along a lateral axis until you are happy with the balance. Now consider the design of the GRAVITON® Ti.

The GRAVITON® Ti is a 3-part design with hollow sections at the front, tessellated sections through the middle and solid sections toward the back by the pivot point. At a macro level, the triangular structures across the components can be appreciated and these exist not only in basic two-dimensional views but also when appreciating the structures in a three-dimensional helical perspective. At a micro level, the triangular geometry is also found internally within the middle section where Wilson Benesch has designed the counterbalance to contain a repeating tessellated latticed structure within the titanium.

The tessellated structures impart multiple advantages:

- Maximum stiffness across the counterbalance.

- Minimal material use – there is zero redundance of materials in the GRAVITON® Ti Armwand. Wilson Benesch have reduced the mass of the armwand without compromising its function. This is most easily appreciated when observing the hollow structure at the top of the armwand where Wilson Benesch reduced the mass to maintain the perfect centre of gravity across the whole armwand.

- Optimal energy damping. The complex internal geometry of the counterbalance forms a highly damped structure that also benefits from powdered titanium internal sections that act like sandbags to absorb energy.

Selective Laser Sintered (SLS) Manufacturing

To manufacture a metal component with this level of detail, you require a manufacturing process of unparalleled precision and accuracy. The structures incorporate hollow sections, tessellated sections and sections where titanium powder has been intentionally left un-sintered. These complex structures could only have been achieved through a Selective Laser Sintered Manufacturing process. This is the only tonearm in the world that uses SLS and the structures are now registered designs.

The Dohmann Edition

Dohmann Audio is a turntable specialist. Our focus is to make the best turntables leveraging our know how and we are always asked to recommend tonearms. We are happy to recommend a variety of tonearms to our clients, depending on their musical preferences, needs and budget. We even offer a selection of well curated options that we can source for them if that’s what they want. When we discovered and auditioned the GRAVITON® Ti, we really wanted to offer it to the community of Dohmann turntable owners.

We approached Wilson Benesch and they were very kind to agree to collaborate with us and create a Dohmann Audio version of the GRAVITON® Ti. This is the first time that we have entered an OEM collaboration of this type and it was a very enjoyable process. The GRAVITON® Ti was originally designed as part of the Wilson Benesch GMT analog system. To fit the arm on a Dohmann turntable required a re-design of the supporting structure and the ability to fit on a Dohmann floating armboard. A prototype was exhibited in the Dohmann Audio room at the 2025 Munich High End Show and after some final design tweaks, the Dohmann Edition became available in July 2025.

The GRAVITON® Ti Dohmann Edition comes with a Mk3 Dohmann Advanced Composite Armboard.

How does it sound on a Dohmann turntable?

We feel that we need to be careful in describing the sound of a component as there are many variables that have to be defined for the description to have any utility. It is impossible to qualify a sound without describing the room, the various components in the hi-fi system, etc. However, in situations where the room and components stay the same and only the tonearm is changed, we can say that the overwhelming feedback is that the GRAVITON® Ti is the most open, natural, uncoloured sound experienced in these auditions. We are comfortable to share the following observations:

Transparency – The ultimate sound quality objective of a tonearm is to be ‘sonically invisible’, meaning to make absolutely no sonic contribution to the sound so that the highest signal fidelity is achieved. In our experience, it is virtually impossible for a tonearm to be completely sonically invisible however the GRAVITON® Ti achieves the closet performance to that ideal that we have ever experienced.

Detail – The GRAVITON® Ti has the ability to render and communicate a lot more information, making it possible to hear micro-details in the performance that have not been evident before. This is one of the most obvious observations about this tonearm and it makes a significant impact on the listening experience. Subtle, nuanced details appear everywhere – in the timbral quality of the instrument, in the vocal, in the tonal hues between voices, in the rise and decay of a note in space…

Spatial information – The GRAVITON® Ti has the ability to communicate the cues and information in a recording that build a mental picture within the listener of the space around a performer, which is very evident in live recordings. Furthermore, the location of different instruments in the soundstage is extraordinary, giving a more visceral feeling of being able to reach out and touch a performer.

Soundstage – The soundstage opens up in all three dimensions. Immediately obvious is the width and height and then you sense that the depth has moved back and the performance has a more palpable, 3D impression.

Separation – The GRAVITON® Ti has the ability to allow the listener to track each individual instrument with seemingly less effort while still maintaining the ebb and flow of the whole performance. It feels like each instrument has its own space while at the same time the performance as a whole is integrated and natural.

As with most extreme or no-compromise designs, the cost of manufacturing such a piece of equipment is very high. It is unfortunate that this level of cost precludes the arm from being experienced by many music-lovers but this is an unfortunate reality for components of this nature. We are glad that someone even attempted to make such a tonearm and that it exists as an option for people to experience. Given the response that this tonearm has received from very discerning audiophiles and from our own experience, we can confidently say that for those that have a highly discriminating system and are desiring to experience the ultimate in fidelity, the ultimate in hearing the information that is contained in the groove of a record in its purest form, the GRAVITON® Ti represents genuine value.

Videos

Pioneering Materials Science in Audio: Wilson Benesch & Carbon Fibre Composites

Specifications

| Description | Kinematic bearing provides 3-point location ensuring zero Brinelling and the optimal hertzian forces to ensure energy transfer through two different materials. Bearing is designed to allow easy change of Graviton® Armwand in less than a minute. Shortest possible lead out wire to avoid signal corruption. |

|---|---|

| Internal Wiring | Silver / Teflon wire |

| Effective Length | 304.8mm |

| Mounting Distance | 291.6mm |

| Offset angle | 18° |

| Overhang | 13.2mm |

| Effective Tonearm Mass | 14g |

| Cartridge Weight Range | All possible |

Adjustment Information

| VTA and SRA | Please note that the Piezo-Driven VTA Mechanism is not available on the Dohmann Edition of the GRAVITON® Ti.

The arm pivot can be precisely raised and lowered for VTA and SRA adjustment. This is achieved via a collar that can be loosened to “slip mode” allowing very fine adjustments before final locking. Once locked if forms a super uniform pressure on the hardened steel post for even energy dissipation into the ACA. |

|---|---|

| AZIMUTH | The gross azimuth adjustment uses an offset counterweight system which achieves quick and simple azimuth adjustment with lock screw. The fine azimuth adjustment can then be precisely done via a weight “cross” screw inside the counterweight that is adjusted using small allen key. This is a very well thought out mechanism that maintains the rigidity of the system. |

| VTF | Vertical Tracking Force is also adjusted in two ways. Gross adjustment is by moving the large counterweight forward and aft and locking this by set screw and allen key. Very fine VTF is then available via a smaller screw weight located inside the larger counterweight which is used to adjust to fractions of a gram in downforce. |

| OVERHANG AND OFFSET | The alignment parameters are precisely adjusted for the WB cartridges. Other cartridges can be adjusted using the headshell surface slots. |

Further information

Please contact a Dohmann International partner or Dohmann Audio for pricing information on the GRAVITON® Ti.